AHU Coil Cleaning Chemicals

The Problem: Contaminated Evaporator/Condenser, AHU Coils

- Dirt, Soot and Grimy Deposit

- Oxide Film Build-up

- Reduced Air-flow

- Lower Cooling Efficiency

- Reduced Evaporator / Condenser Life

- Frequent Compressor Failure

- Increased Energy Consumption Per Ton of Refrigeration

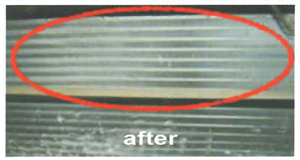

The Solution: Vaniklin-WB treatment

- Cleans, renders good-as-new, coils, condenser surfaces and filters

- Brightens, removes tarnish

- Provides free, unhindered air circulation

- Enhances cooling

- Increases life span of condenser & evaporator coil

- Provides trouble-free compressor performance

- Reduces energy consumption per ton of refrigeration

Product Features

- No steaming, scrubbing of brushing required

- Supplied in highly concentrated form

- Non-corrosive to most metals including brass, aluminm, copper, mild steel

- Safeto handle and dispose

- No special storage required

General Directions For Use

- Shut off system. In certain cases, e.g. comfort A/C jobs, this may not be necessary.

- Mix 1 part Vaniklin-Wb with 1 part water. For less stubborn deposits, use higher dilution ratio (1:2 or 1:3).

- Spay directly onto coil using a low-pressure hand sprayer. (For multi-bank coils, a mechanical spray pump may be needed). Spray directly over entire surface to be cleaned.

- Rinse thoroughly with water after 3-5 minutes or when foam settles. Dirt is lifted, in fact, it just vanishes.

- Window units can be easily cleaned by dipping into 1:1 solution of Vaniklin-Wb for 3-5 minutes.